LF of America uses the most advanced contract filling equipment to fulfill orders big and small. We also manufacture these innovative liquid packaging machines and distribute the most highly advanced contract filling equipment available. These unit-dose and automated liquid packaging systems use injection mold technology instead of the “Blow Fill Seal” process. Injection mold technology offers

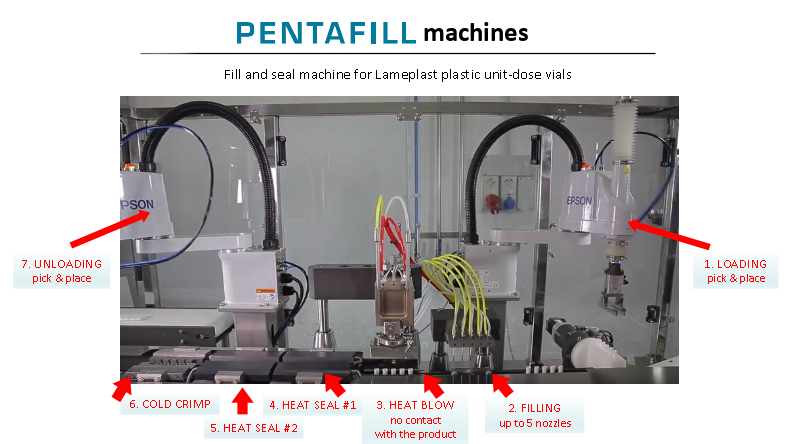

LF of America uses the most advanced contract filling equipment to fulfill orders big and small. We also manufacture these innovative liquid packaging machines and distribute the most highly advanced contract filling equipment available. These unit-dose and automated liquid packaging systems use injection mold technology instead of the “Blow Fill Seal” process. Injection mold technology offers companies various benefits unmatched by blow fill seal machines. Learn more about the differences between these two processes and what makes our Pentafill machines superior to our competitors in the article below. To request a free product sample or to speak with one of our team members about packaging services or manufacturing contract filling equipment call 561-988-0303.

Differences Between Injection Molding & Blow Fill Seal

Injection Molding Technology + Fill & Seal

Two-step process that molds vials then transfer them to the filling line to be filled and heat sealed. (No risk of contact between product and heat)

Added flexibility that ranges from small batches at 1,500 vials per hour to full-scale production at 15,000 vials per hour.

Smaller dimensions mean machines fit in most existing contract filling environments.

Improved end-user experience. Easily switch out or replace damaged, worn, or old parts.

Less than half of the cost of traditional BFS machines with the same production capacity.

More environmentally friendly and no excessively wasted plastic material.

Provides the option for multilayer packaging designs and calibrated drops.

Blow Fill Seal (BFS)

One-step process that blows and fills vials at the same time. (Risk of contact between product and heat)

3 working shifts necessary once started. Only capable of full-scale production at roughly 10,000 vials per hour without being able to stop the machine.

Large dimensions with a recommended minimum room size of 500-600 square feet.

Halted production time due to the changeover of molds.

Higher initial financial investment and overall cost.

Large amount of plastic waste is cut from the parison and then disposed of.

Extremely complex set up, maintenance, and operating instructions that require highly skilled and well-trained personnel.

Watch our very own Pentafill A25 machine in action in the video below.

LF of America also provides custom packaging services for OTC cosmetics and pharmaceuticals. We manufacture packages according to the specific unit-dose size and offer them in whatever color or shape you might want. You can also add your own custom text, emboss, logo, and more. To learn more about our custom packing services, Click Here.

LF of America specializes in filling, sealing, packaging, and manufacturing unique unit-dose delivery systems for liquid products in a variety of industries. Our company also manufactures contract filling equipment and supplies our Pentafill machines to companies around the world. Our contract filling services are fulfilled out of our state of the art facility in Boca Raton, FL while our contract filling equipment is manufactured through our professional partnership with Lameplast Group.

Read more industry-related news on our Blog. Visit our service pages for a more thorough understanding of all our contract packaging, contract filling, and packaging manufacturing services. To receive a free product sample Contact Us or call 561-988-0303.

Facebook | Google+ | YouTube

Contract Filling Equipment